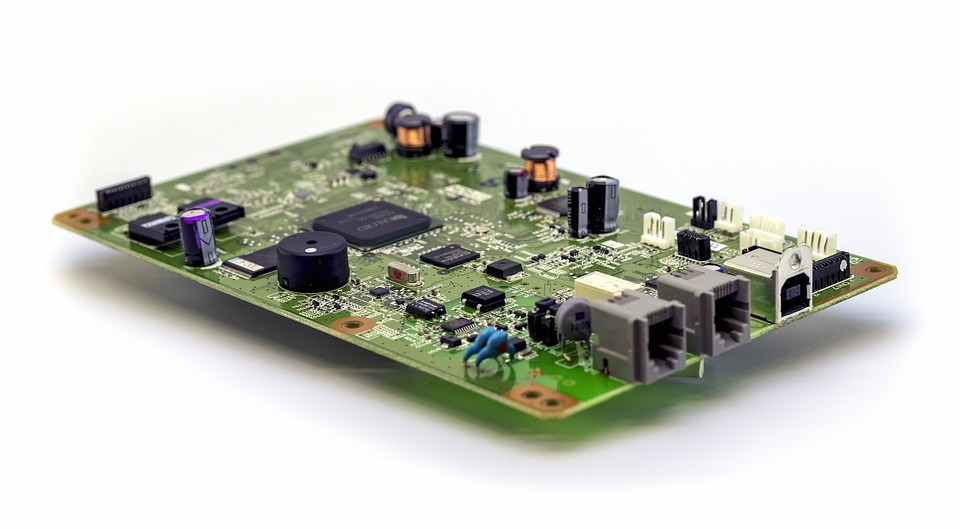

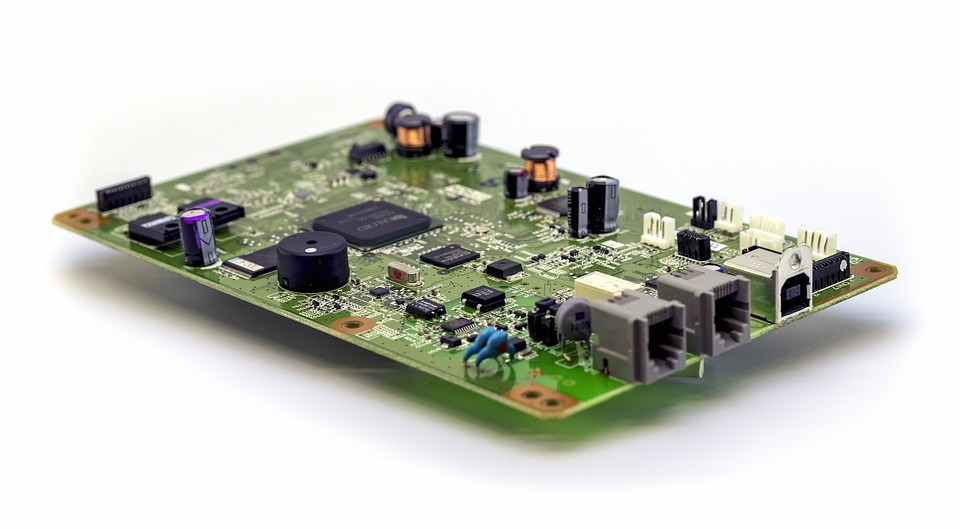

A printed circuit board prototype or otherwise known as a PCB prototype is a representation or sample of what the concluding printed circuit board would look as well as work like. Printed circuit board prototyping is an indispensable procedure which comes before mass fabrication and the following introduction of novel printed circuit boards into the market. This procedure finds out whether a recommended Printed Circuit Board Assembly & design would perform as probable thus finding out any probable flaws and therefore facilitating the designers to carry out any required transformations. Any other enhancements or alternatives the designers might imagine are moreover launched at this stage. The mass fabrication of any novel product leave alone PCB circuit boards cannot plainly just start without the prototyping stage.

Furthermore, prototyping wouldn’t essentially expose any flaws as sometimes the design is ideal. PCB prototyping in this scenario would be employed corroborate and re-determine that the printed circuit board performance is steady. The fabricators or the clients can then provide their outlook concerning the PCB together with other recommendations/enhancements they might possess. The printed circuit board designers must always be ready for any probable results and therefore any modification at this stage must further not be measured as an additional cost. Bypassing prototyping as well as involved in the mass fabrication of a PCB just for it to fail it will surely be disastrous with regard to wasted endeavor, time as well as dollars.

The subsequent are the general stages in printed circuit board prototyping. The foremost is known as the breadboard test or evidence of principle. This makes sure in case the reason behind the PCB is feasible. Next is evaluating the size (favorable dimensions) characteristics of the predictable PCB. After this stage, an illustration model is created and in the case accepted the last stage which is working and looks are started. Whatever is accomplished at this moment is contiguous to what the real printed circuit board would look like. In general, in prototyping for PCB circuit boards, the imitation of current flow in the circuit board and the state of the circuitry are the 2 key significant procedures. It is just unless the simulated system functions as needed that actual elements and materials are executed for the concluding model/prototype.

The manufacture of prototypes is a procedure restricted by time – it is supposed to consume the smallest time fraction feasible to prepare the way for the actual fabrication. Firms providing printed circuit board prototyping services are moreover probable to be engaged in fabrication. As such, these firms work hard to design good/outstanding prototypes. Enhancement in technology & more so mechanization has accelerated the procedures of prototyping and fabricating printed circuit boards and created them as free of error as probable. For that reason, It is prudent to pick a PCB firm that has the latest technology, a potential that would make sure that the error margin is approximately nil, the utilization of injurious chemicals is neglected, and printed circuit board sizes are made as small as probable nevertheless just as they are as essential for recent electronic gadgets.

Making the prototype exactly right is an enormous step towards a better product. Unluckily, a number of fabricators attempt to get through this significant stage of manufacture as rapidly as probable.

Printed Circuit Board Assembly

Firms that offer to prototype also offer printed circuit board assembly services. You can find easily the internet that can fulfill your business needs.